These devices can print in a range of materials from various plastics to metals to sugar and chocolate. They range in price and capability from tens or even hundreds of thousands of dollars for large, highly developed machines that can print metal parts that are ready to be used, to a few hundred dollars for hobbyist machines that will print in one kind of plastic and that require more hand-holding to produce satisfactory results. Below is a picture of a MakerBot Replicator 2. This might be described as a pro-sumer machine. It is a well developed device that is designed to print in one kind of plastic. Right now it costs around $2,200.

Below is a chart showing the usage by printer type.

|

| Source: Moilanen, J. & Vadén, T.: Manufacturing in motion: first survey on the 3D printing community, Statistical Studies of Peer Production. |

I admit that it doesn't have the elegance of the Replicator 2, and looks more like the love-child of an Erector Set and a Heathkit (for those of you who remember Heathkits) but it only costs one-third of what the Replicator 2 costs and without modification can print in two types of plastic.

The way they work has been described as a robot-controlled hot-melt glue gun. The gold-colored stage in the picture above moves side-to-side and forward and back, as well as up and down. There is a hot orifice through which molten plastic is extruded in thin layers (in the case of this device as thin as 0.1 mm) as the stage moves around, thus "drawing" the object. This technique is referred to as Fused Filament Fabrication (FFF).

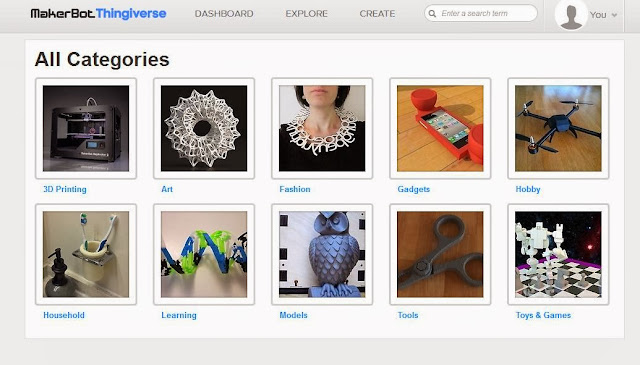

There's one more element that I want to mention, and that is Thingiverse. Thingiverse is a website/database run by MakerBot. Here people upload 3D printable models that they have developed and that can be downloaded for free.

Above you can see a screen shot of the main page. Most of the categories are self-explanatory. The 3D Printing category is mostly parts for various 3D printers. The website gives the user access to literally thousands of printable plans. Some wags have observed that 3D printers give everyone the ability to print their own tchotchkes. Those plastic Yoda statues you want to give your friends are now within reach. There are, however, some exciting and worthwhile things going on that I will talk about in later posts. I will also describe my progress in assembling my printer and learning to use it.

WAK -- great to see "you" and anxiously await your figuring out how to put yourself in 3D on this here blog.

ReplyDeleteThis is really cool. I saw a 3d printer in Boston printing a chess set. Is it possible to print a pipe for your organ using this?

ReplyDeleteThank you, NN. I'm not quite sure what that means but I'm all about 3D

ReplyDeleteM@,

ReplyDeleteI've got the printer working and I'm going to do a post about it. I hadn't really thought about using it for the pipe organ. The build volume wouldn't be big enough to make anything other than the smallest pipes although that might be worth a try. Where it might come in handy though is in making custom fittings to connect all the plumbing. I have to get in the right frame of mind. Now I look for parts in my bins and storage boxes, and at Lowes. I have to remember there is a whole new world of things I can just make.

Wow that was odd. I just wrote an very long comment but after I clicked

ReplyDeletesubmit my comment didn't appear. Grrrr... well I'm

not writing all that over again. Anyhow, just wanted to say excellent blog!

My web page: best 3d printer

3D Printer is very great.

ReplyDeleteThank you for letting me know about this product.

see it here

Great post, you have pointed out some fantastic points , I likewise think this s a very wonderful website.

ReplyDeleteCheap 3d Printer

Great post, you have pointed out some fantastic points , I likewise think this s a very wonderful website.

ReplyDeleteCheap 3d Printer

I can set up my new idea from this post. It gives in depth information. Thanks for this valuable information for all,..

ReplyDeletedruk 3d szkolenie